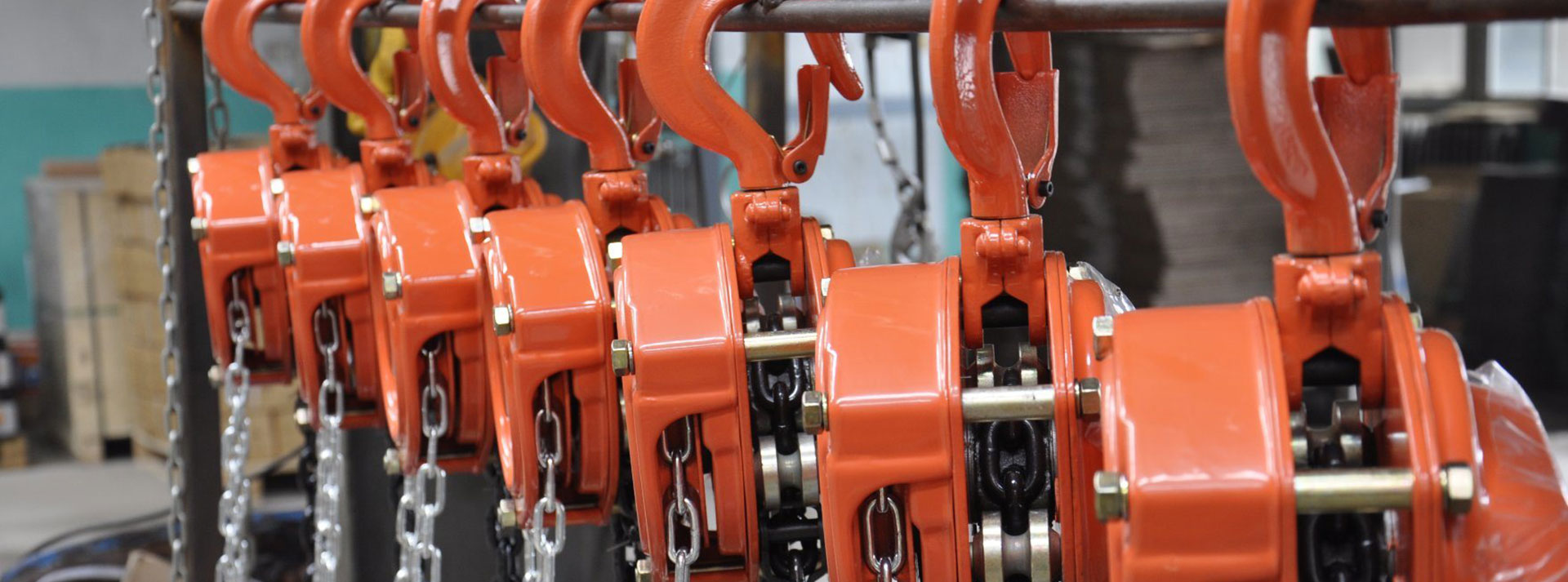

Carascal is often called a differential pulley and is used for load lifting. Meanwhile, the Weston differential pulley is also called.

It is a kind of chain hoist used to manually lift very heavy objects such as car engines. The loose portion of a continuous chain surrounding the pulleys is used by pulling.

It was first used in the UK in 1854. 1862 exhibited five sizes of hoists capable of handling loads from 510 kg to 3 tons at the London International Fair and received the original medal of practice, practical benefit and success.

The Regulation on the Health and Safety Conditions in the Use of Work Equipment issued by the Ministry of Labor and Social Security accepts hoists as dangerous vehicles in terms of employee health and property safety of enterprises. Hoists, which belong to the group of lifting and transmitting vehicles, should be inspected and inspected periodically at least once a year. However, if a different period is stipulated in other legal regulations, it must be observed.

When using carascals, the safe working load must not be exceeded in any way. Safe working loads on the hoists must be clearly indicated. It must also be tested and thoroughly examined by an authorized person prior to commissioning.

The standards that are taken as basis in the control and inspection works carried out by the competent authorities are as follows:

TS EN 12385-3 Steel wire ropes - Safety - Part 3: Instructions for use and maintenance

TS EN 818-6 + A1 Short link chain - For lifting purposes - Safety - Section 6: Chain slings - Technical specification for use and maintenance information to be supplied by the manufacturer

Although the design of the hoists is simple, it works great in terms of the load they lift, and as with all such vehicles, there are risks to the health of employees if they are not maintained regularly.

The application is received, the contract is followed and the organization, which product, vehicle and work equipment, what type of survey or inspection is determined.

An expert team is guided by the relevant examinations and the evaluations requested by the organization are performed NDT or visually.

The data obtained as a result of the inspection is evaluated by the expert auditors and the accredited inspection report is submitted to the company.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.