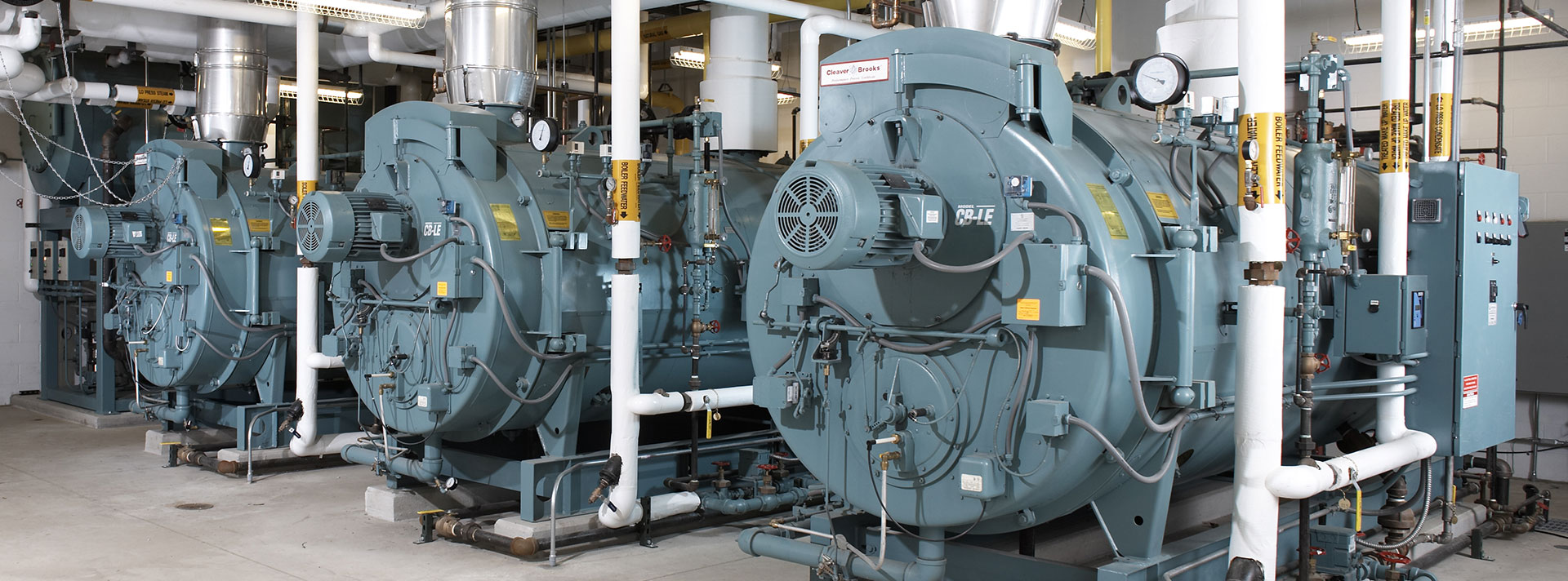

Steam boilers are closed containers where water or other liquid is heated under pressure. This liquid is then removed from the boiler for use in many processes or power generation. For energy production, steam is produced at very high pressure and temperature in steam boilers.

In 200 BC, it is known that in ancient Greece, steam produced in a heated vessel from below was used to spin the wheel. Until today steam boilers have shown great improvement. Steam producing boilers are now classified in various ways.

The main purpose of steam boilers is to produce steam, and therefore the main classification is the way steam is produced and consumed. Accordingly, there are two main boiler classes: industrial steam generators and power generation boilers.

Steam boilers have a heat source operating with water and oil, coal or gas. The boiler transfers the heat to the container, thus converting the water into steam. This steam exits from the boiler with pipes and is transported to a point that can be used by cleaning, supplying power to an equipment, providing heat, or other means.

In closed steam boilers, all of the steam turns into water and returns to the container. Therefore, these systems are very efficient and cost-effective to use. However, in some industrial establishments, steam is contaminated and cannot be reused. These systems are also called open systems.

All boilers are equipped with a safety valve that allows the release of excess steam to prevent explosions. Consequently, high pressure is always a danger and it is important to carry out regular maintenance of steam boilers.

The standards that are taken as basis in the control and inspection works carried out by the competent authorities are as follows:

TS 2025 Steam boilers operating - General rules of inspection and maintenance

TS EN 13445-5 Pressure receptacles - Non-contact - Section 5: Inspection and testing

TSE CEN / EN 13445-9 Non-fire pressure vessels - Part 9: Compliance of most 13445 series with ISO 16528

ISO 16528 Boilers and pressure vessels

The application is received, the contract is followed and the organization, which product, vehicle and work equipment, what type of survey or inspection is determined.

An expert team is guided by the relevant examinations and the evaluations requested by the organization are performed NDT or visually.

The data obtained as a result of the inspection is evaluated by the expert auditors and the accredited inspection report is submitted to the company.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.