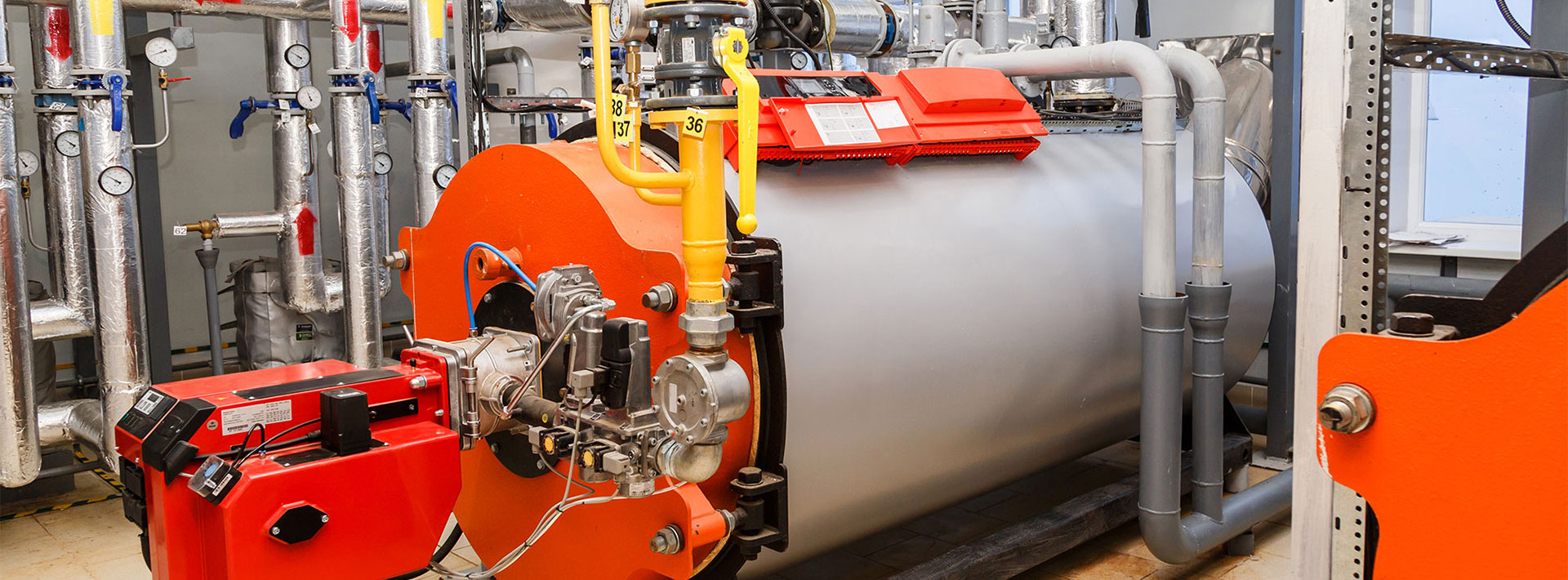

Pressure vessels are designed to hold liquids, vapors or gases at high pressures, and storage tanks, boilers and heat exchangers used in oil refining plants, chemical plants and many industrial sectors are pressure vessels.

Pressure vessels have different operating limits depending on the design and intended use. If operated outside these limits, the pressure receptacles will be damaged and potentially cause destructive failures and environmental damage.

Because they operate under very high pressures, a damaged or torn pressure vessel can cause fire and explosion or toxic gas leaks and can be extremely dangerous. Therefore, the safety of pressure vessels is mandatory.

Several standards have been developed and implemented for the construction, maintenance and inspection of pressure vessels. The leading standards are those prepared by the American Mechanical Engineers Association (ASME) (Section VIII Boiler and pressure vessels standard) and the API 510 standard (pressure vessels inspection standard) prepared by the American Petroleum Institute (API).

ASME Part VIII is the part of the boiler and pressure vessels standard covering pressure vessels. It contains detailed requirements for the design, manufacture, testing, inspection and certification of both hot and non-fired pressure vessels.

The API 510 standard covers inspection, repair, modification and reorganization of pressure vessels and pressure relief devices protecting these vessels.

What is essential for both standards is that pressure vessels are checked and inspected once before service and after each change or major repair. During these studies, thickness assessment, stress analysis, inspection of pressure relief valves and hydrostatic pressure tests should be performed. In addition, surface inspection, insulation, structural connections and any welds and joints should be examined.

Our company provides many pressure vessels and installations inspection services to its customers with a strong technological infrastructure and a trained and experienced staff. Some of the main services provided are:

Boiler periodic inspection and inspection

Periodical control and inspection of steam boiler

Periodic control and inspection of expansion tank

Periodic control and inspection of booster tank

Periodic control and inspection of central heating boiler

Periodic control and inspection of boiler rooms

Periodical inspection and inspection of hot oil boiler

Periodic inspection and inspection of compressor and air tank

Autoclave periodic control and inspection

Firstly, it is determined whether the organization meets the mandatory requirements of the standard and whether to proceed to the next stage.

It is checked whether necessary procedures and audits have been developed and your institution's readiness for evaluation is reviewed.

The findings that arise in the first two stages are evaluated and after all corrective actions are reviewed, document preparation is started.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.