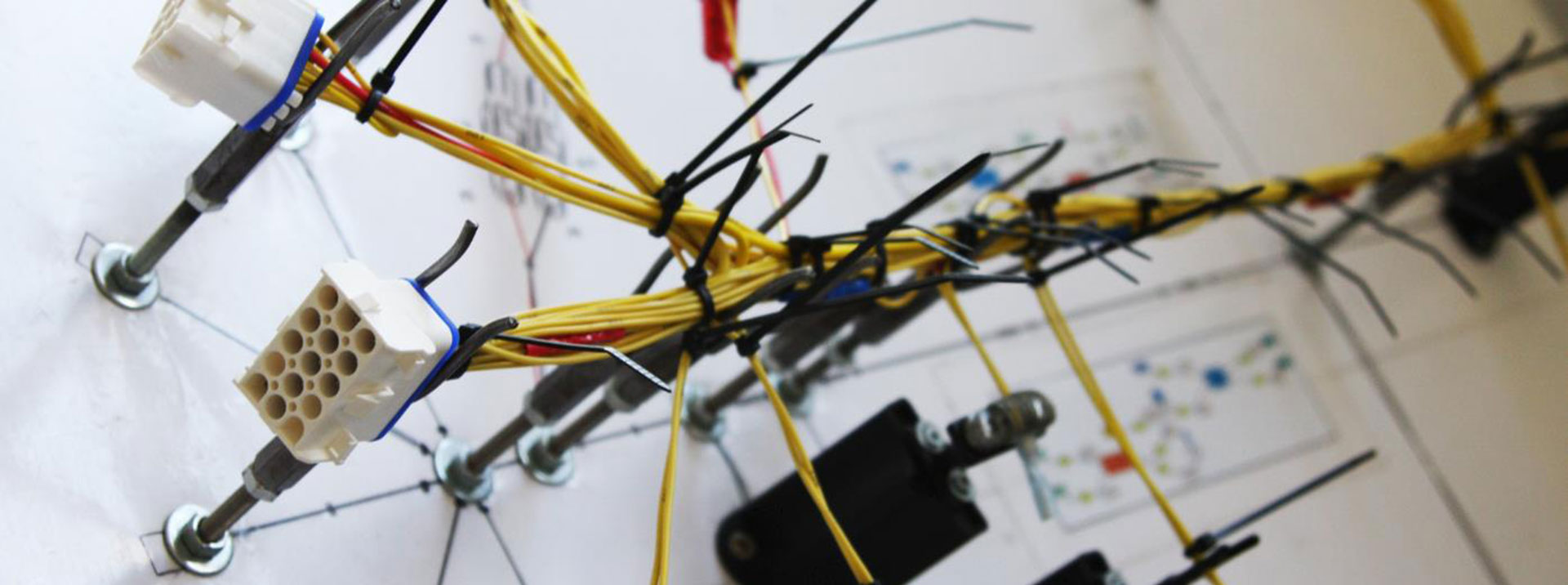

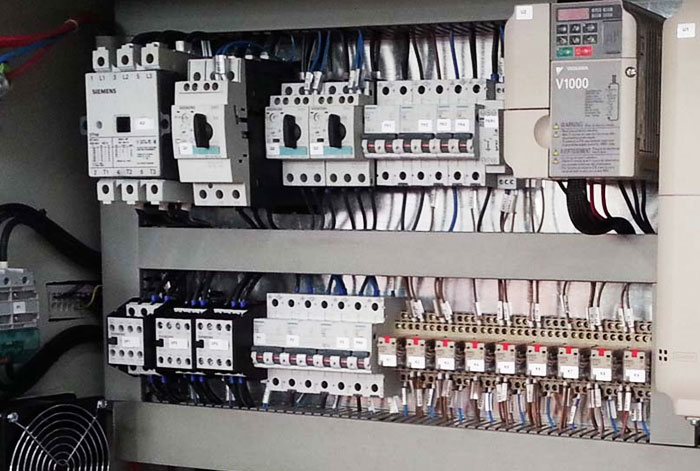

During the production activities of the companies, various tests are carried out to determine the quality of the panels and cables and then for the maintenance operations during use. Special test devices are used for this purpose. These devices are automatic test devices used to test and verify electrical connections on a panel or anywhere installed.

With these devices, it is checked that the cable is laid in accordance with the design, in accordance with the plans and of the expected quality. In general, three basic points are identified with these devices: the suitability of the cables, the quality of the cabling and the functionality of the cables.

Under normal conditions, all electrical current delivered through a conductive cable reaches its destination. But sometimes for a variety of reasons, some current disappears along the way. The cables are insulated with a resistant sheath, which typically uses the conductivity of the copper or aluminum core.

However, even if this insulation is in place, a fault in the insulation may still cause the current to escape. This will damage electrical circuits and machines. The purpose of the tests to determine the panel and cable test quality is to determine whether the insulation performs at an effective and safe level.

Here are a few standards that are based on panel and cable quality testing by competent authorities:

TS EN 60332 Electrical and optical fiber cable tests at risk of fire

TS EN 61034 Measurement of smoke density of burning cables under specified conditions

TS EN 60754 Cables - Test for gases released during combustion of electrical cables

TS 7321 EN 60885 Cables - Electrical test methods

TS EN 60811-403 Electrical and fiber optic cables - Test methods for non-metallic materials - Part 403: Miscellaneous tests - Ozone resistance testing of cross-linked compounds (IEC 60811-403: 2012)

The application is received, the contract and then the product, vehicle and vehicles for which, what kind of service is determined exactly.

The necessary laboratory environment is prepared and the products, tools and instruments requested by the organization are tested by experts with the reference of the existing standards and measurements are made.

The data obtained as a result of meticulously completed tests, measurements and analyzes are evaluated and accredited approved reports are submitted by expert engineers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.