The importance of product testing in all sectors for quality, reliability and durability is indisputable. Product development means time, creativity and resource usage. The most important process in the development process is quality, reliability and durability tests.

Businesses want to make sure that their products will perform as expected. This is an indicator of quality. In addition, even if conditions are not appropriate, the products are expected to show the same performance in all cases. This is reliability and durability.

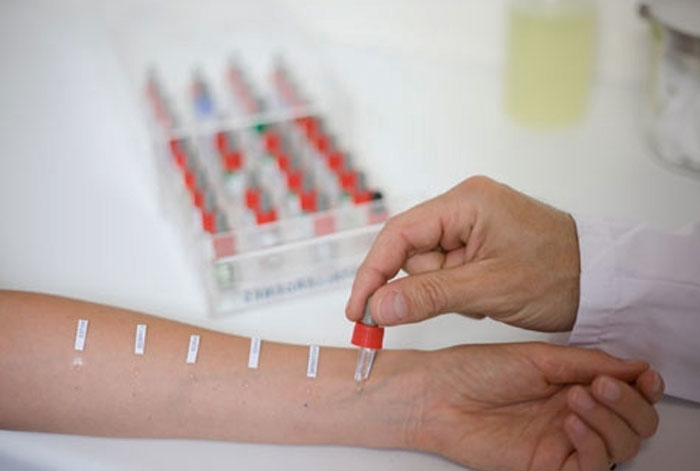

To assess the safety and effectiveness of certain products, such as medical devices, a number of inspection, inspection and approval processes are required within the framework of legal regulations. These devices are devices that support or sustain human life, but devices that do not undergo the necessary tests and inspections may pose a danger to human health.

Producers must go to third-party organizations that are sound, impartial and independent to support their claims regarding their products. Such organizations carry out such tests and measurements either in their own laboratories or in their accredited laboratories.

Specific types of tests include quality assurance, product reliability and life cycle testing. These tests are usually conducted during product development stages. The outcome criteria must be based on realistic expectations. The components that make up the product are evaluated from this perspective.

For example, electronics or raw materials must be of a certain quality. If a medical device is being produced, the components in these devices must have a higher standard than non-medical consumer electronics products. Testing the functionality of the product during the manufacturing process is part of the quality process. The main purpose of reliability tests is to measure performance and durability in the long run and in suitable working environments.

The product aims to find stress tests, design weaknesses and special assembly and material problems. Within this framework, specific tests such as highly accelerated life test and highly accelerated stress test are performed. These tests simulate real life conditions that a product may encounter during its lifetime.

The application is received, the contract and then the product, vehicle and vehicles for which, what kind of service is determined exactly.

The necessary laboratory environment is prepared and the products, tools and instruments requested by the organization are tested by experts with the reference of the existing standards and measurements are made.

The data obtained as a result of meticulously completed tests, measurements and analyzes are evaluated and accredited approved reports are submitted by expert engineers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.