Color fastness is an important quality feature in textile products. For a painted product, the color fading or overflow strength is important. Color fastness refers to the resistance of dyed or printed textile materials to fade or overflow.

There are many factors affecting the color fastness properties of the products. For example, the chemical structure of the fiber is an important factor. The fastness properties of cellulosic fibers dyed with reactive or container dyes are strong. It is very important that the dye is compatible with the fiber.

Another factor affecting the fastness property is the molecular structure of the dye molecule. If the molecules are large in size, a fiber adheres more tightly into the polymer chain cavity. This increases the fastness strength.

The manner in which the dye binds to the fiber or physical form, the amount of dye present in the fiber, ie the depth of shadow, the presence of other chemicals, and the conditions during exposure to the dye, are also factors that influence color fastness properties.

Fastness tests performed in advanced laboratories are not limited to dye fastness. There are a number of fastness tests performed in this context. For example, seawater fastness, pool water fastness, light fastness under hunting conditions, fastness to rusting, fastness to phenolic yellowing, fastness to frosting, fastness to dry cleaning, fastness to hot press, fastness to chlorine / chlorine-free bleaching, fastness to ozone, fastness to sweat, rubbing fastness, solvent fastness and washing fastness are some of them.

Fastness tests performed in advanced laboratories comply with the methods and standards published by domestic and foreign organizations. For example, 66 different color fastness tests by the American Association of Textile Chemists and Colorists (AATCC) have been described for color fastness.

The International Standards Organization (ISO) has established a rating system from 1 to 8 for light fastness and from 1 to 5 for other fastness criteria. It has also developed numerous standards for different fastness situations.

The application is received, the contract and then the product, vehicle and vehicles for which, what kind of service is determined exactly.

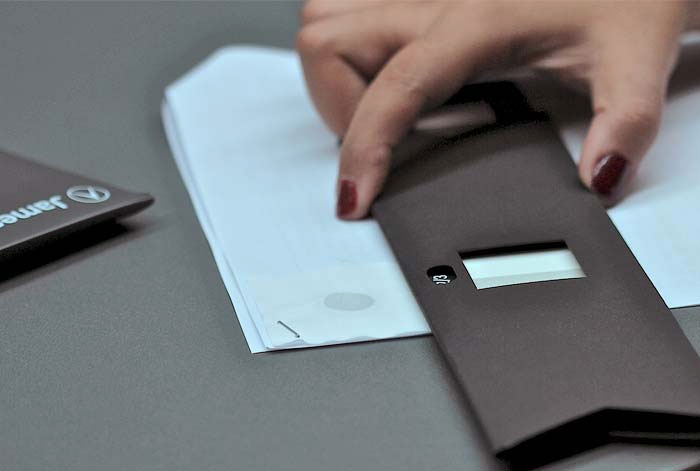

The necessary laboratory environment is prepared and the products, tools and instruments requested by the organization are tested by experts with the reference of the existing standards and measurements are made.

The data obtained as a result of meticulously completed tests, measurements and analyzes are evaluated and accredited approved reports are submitted by expert engineers.

To get an appointment, to get more detailed information or to request an evaluation, you can ask us to fill in our form and reach you.